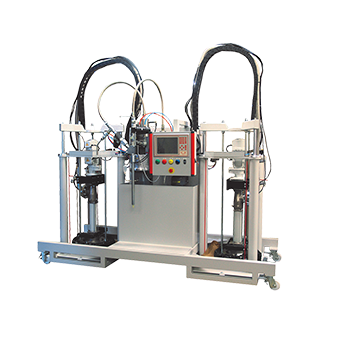

Polymix 1000/2000 Overview

The PolyMix 1000/2000 systems were developed to handle the viscous resins used to bond large composite structures. With the piston metering systems excessive work was put into the material during metering, reducing the open time and therefore compromising the process.

2KM resolved this issue by utilising progressive cavity feeding system linked to large capacity gear pumps rotating at a low speed.

This format of machine enables the high flow rate of viscous adhesives with very little temperature increase.

| Metering technology | Progressive cavity feeding pumps and gear metering system |

| Ratio range | 20:100 through 100:100 to 100:20 |

| Output (depending on Viscosity) | Up to 10 litres per min. (PolyMix 1000) Up to 20 litres per min. (PolyMix 2000) |

| Viscosity range | Up to 1,000,000 cps |

| Maximum operating pressures | 200 bar |

| Mixing options | High pressure, large bore static mixer with reinforced plastic elements |

| Metering control | Spindle type Screw flowmeters |

| Control systems | 2KM Microprocessor based Siemens S700 systems |

| Services | 11.5 KW PolyMix 1000 16kW PolyMix 2000 Low consumption compressed air |

| Options available | Refillable containers (2000R) Towable version with compressor & cable reel Large swing arm |

| Area of application | Industry | Process |

|---|---|---|

| Composites | Wind Energy | Wind Blade production, bonding of shells |

| Typical materials processed: |

|---|

| Epoxy Polyurethane Methacrylate |

PolyMIX 1000/2000

The PolyMix 1000/2000 systems were developed to handle the viscous resins used to bond large composite structures. With the piston metering systems excessive work was put into the material during metering, reducing the open time and therefore compromising the process.

2KM resolved this issue by utilising progressive cavity feeding system linked to large capacity gear pumps rotating at a low speed.

This format of machine enables the high flow rate of viscous adhesives with very little temperature increase.

Composites

Wind Energy

Wind Blade production, bonding of shells

| Metering technology | Progressive cavity feeding pumps and gear metering system |

| Ratio range | 20:100 through 100:100 to 100:20 |

| Output (depending on Viscosity) | Up to 10 litres per min. (PolyMix 1000) Up to 20 litres per min. (PolyMix 2000) |

| Viscosity range | Up to 1,000,000 cps |

| Maximum operating pressures | 200 bar |

| Mixing options | High pressure, large bore static mixer with reinforced plastic elements |

| Metering control | Spindle type Screw flowmeters |

| Control systems | 2KM Microprocessor based Siemens S700 systems |

| Services | 11.5 KW PolyMix 1000 16kW PolyMix 2000 Low consumption compressed air |

| Options available | Refillable containers (2000R) Towable version with compressor & cable reel Large swing arm |

Epoxy

Polyurethane

Methacrylate